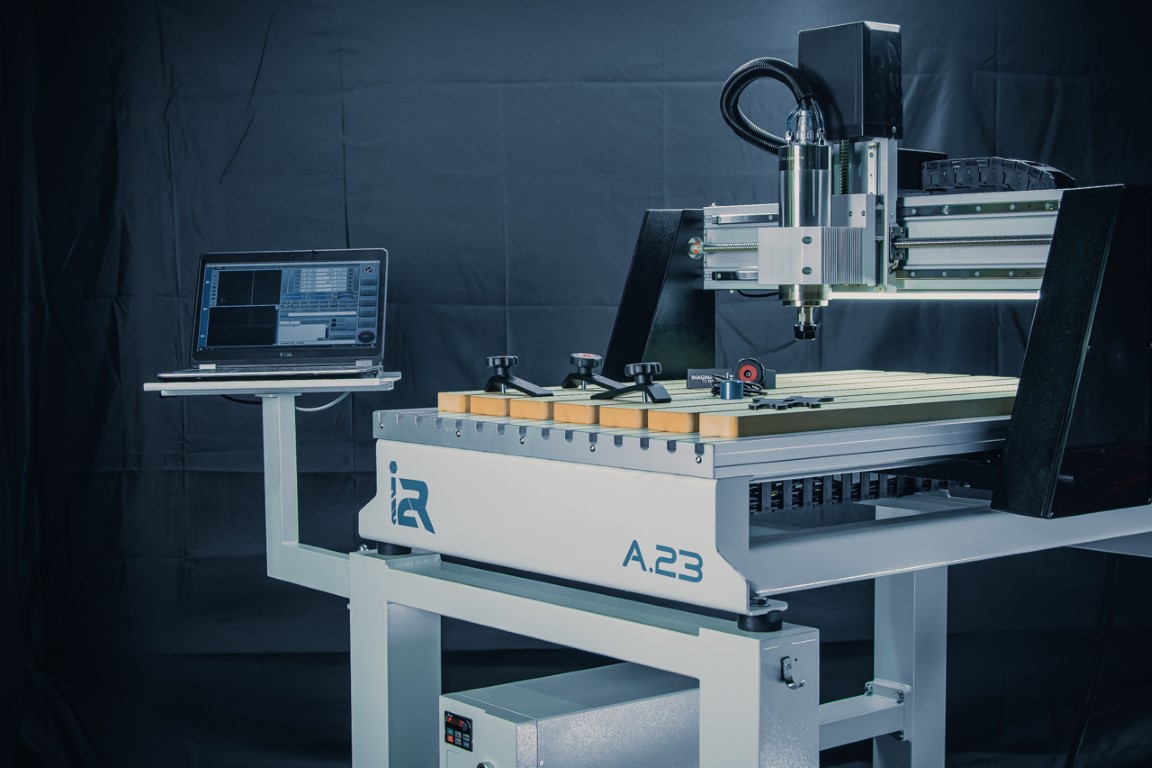

i2R A-Series CNC Router

The i2R A-Series CNC Router is the best small format CNC router on the market that provides accuracy, performance, longevity, ease of use and simple fun! It was designed with home hobbyist, DIY workshops, small business and professional alike and with the many options of addition functionality to be added when the user is ready such as the 4th axis kit. We at BG precision only sell the i2R CNC routers with a PC based control interface as we believe it’s the most intuitive interface with plenty of functionality and suitable for non-experienced CNC operators. The i2R A-Series is capable of machining all woods, most plastics, the correct grades of brass and aluminium.

- UCCNC Industrial 4-axis CNC Controller

- 2.2KW High Frequency Electro Spindle

- Integrated Liquid Cooling System

- Interlocking Aluminium Table

- MDF Sacrificial Spoilboards

- Precision Ball Screws

- Prismatic Guides in all Axes

- Auto Tool Touch-off Plate

- UCCNC PC based Software included

- Pre wired to accept our optional Rotary Kit

- Pre Wired to accept our optional 6w Diode Laser Kit

- Travel sizes | 610mm x 610mm | 915mm | 1220mm

i2R CNC APPLICATIONS

FURNITURE

Whether you’re simply cutting out 2D furniture components, producing an accent inlay, or an ornate 3D wood appliqué, the applications for a CNC router within the woodworking trade are nearly countless.

FABRICATION

Need to produce a unique component? Wood, Aluminium, Brass, Composites, Phenolic, Foam, Plastic… If it can be cut with a spinning bit, the i2R CNC can produce it quickly and accurately.

3D CARVING

The i2R A-Series capacity and accuracy make each machine a 3D carving powerhouse. From large three dimensional objects, to fine furniture accents, you’ll quickly produce accurate 3D carvings.

PROTOTYPING

Many of our present customers already own large, fast, and very expensive CNC machining centres. They turn to the i2R A-Series CNC when they want a small, yet accurate machine to produce one-off components and prototypes.

SIGN MAKING

The ability to use a CNC machining centre to carve letters and design elements into wood, plastic and aluminium has transformed the sign industry. We offer the machines, software and accessories to produce nearly any sign you can imagine.

MILLWORK

Reproducing historic architectural components is a snap with the i2R A-Series. Brackets, capitals, arches, corbels, moldings and more can all be produced with ease.

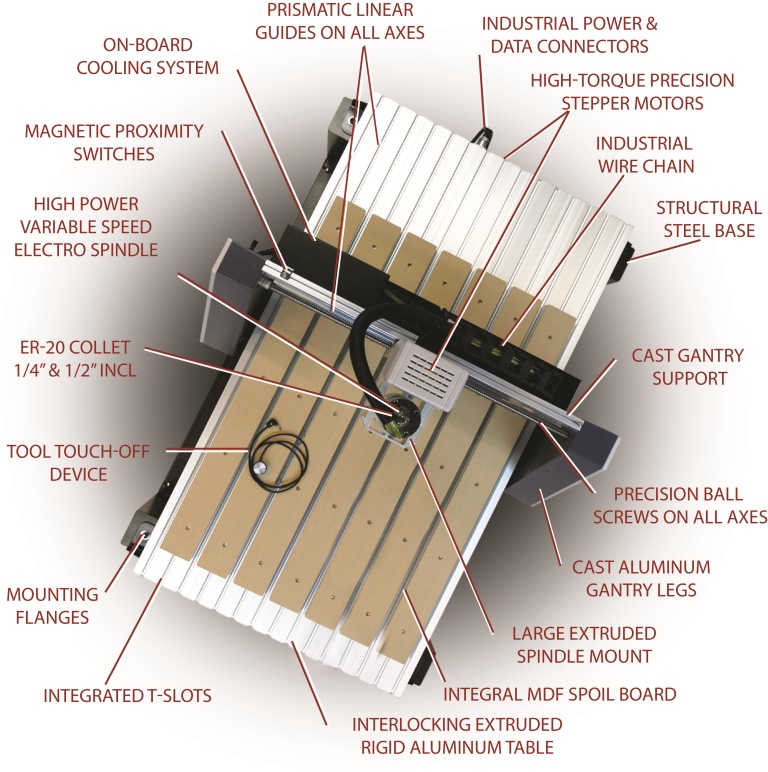

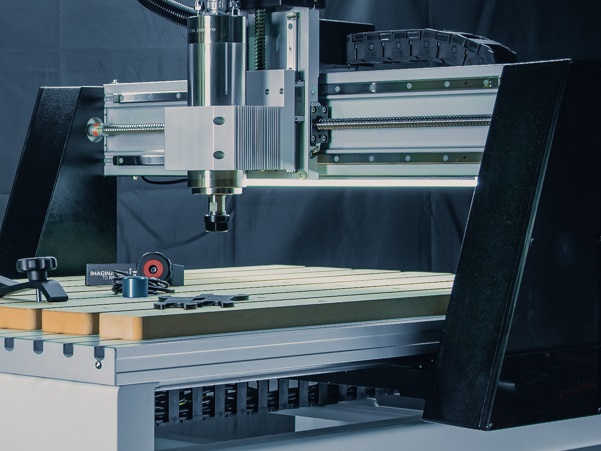

i2R CNC FEATURES

To simplify the machine features please see below the i2R A-series overview. In a nutshell the the i2R A-series was built like an industrial CNC router just scaled down to a small format size. It still uses profiled linear rail and ballscrews which the best types of components available for linear motion. It comes with an industrial high frequency water cooled spindle which has been designed for continuous operation for long toolpath operations. That paired with our proven UCCNC PC based CNC control interface it promises the users interaction with this CNC Router to be a walk in the park.

The i2R CNC Router Advantage

TOOL TOUCH-OFF SENSOR

Each time you install a bit in your i2R CNC machine, you’ll need to accurately determine the length of the new tooling. Simply slide the tool touch-off device beneath the bit, initiate the ‘Auto Touch-Off’ command on your UCCNC interface, and the bit length will automatically be determined and stored in the UCCNC software.

SUPPORTED LINEAR GUIDEWAYS

Our linear guideways utilise recirculating bearings between a prismatic rail and a bearing block. The coefficient of friction on our linear guides is only a small fraction of what is created by traditional round guides, and are able to take loads in all directions. With these features, our CNC machines achieve high precision and greatly enhanced moving accuracy.

CAST GANTRY SUPPORTS

Heavy components travelling at a high rate of speed generate high forces of inertia. The horizontal gantry support (located beneath the table), and the vertical gantry legs take the brunt of that force. Each gravity cast aluminium component is powder coated and engineered to be completely overqualified for their job.

STRUCTURAL STEEL FRAME

You wouldn’t build a home on a compromised foundation…Nor should you build a CNC router on one. Our welded, structural steel frame is heavy, rigid, and accurate. It supports the weight of your i2R A-series machine with ease. It also offers mounting flanges in each corner to secure your machine to an optional the i2R A-series stand, or your work surface.

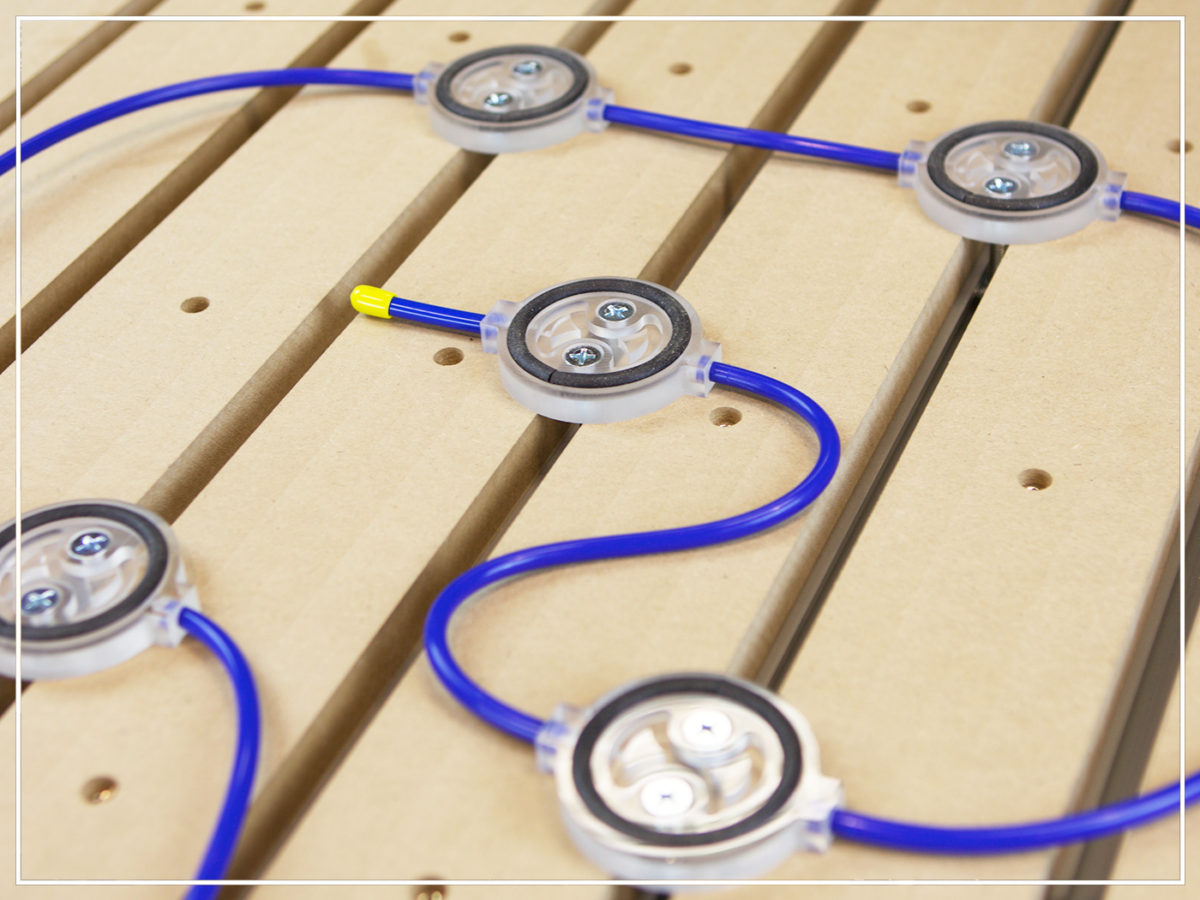

INTERLOCKING ALUMINIUM TABLE

This is a seriously strong table. The massive 30mm thick extruded aluminium table provides a strong, flat surface to support your material. Integrated T-slots allow placement of hold-down clamps in any location, and a sacrificial MDF spoil board ensures that your table will always remain flat and damage free.

HIGH PRECISION BALL-SCREWS

Motion on every axis of every i2R machine is controlled by high-precision ball screws. These ball screws utilise recirculating ball bearings to provide close tolerance and offer unmatched accuracy. Their ability to create low internal friction, while withstanding high thrust loads at high rates of speed, is paramount to the accuracy of each i2R CNC machine.

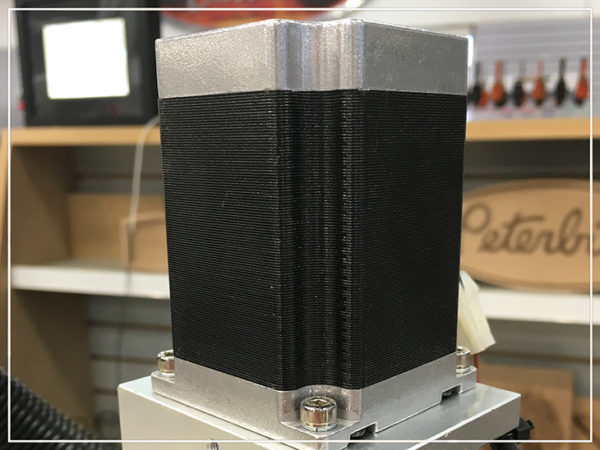

INDUSTRIAL CONNECTORS

The performance of your machine relies upon accurate transfer of data to the stepper motors. Every wire connector found on an i2R machine is of the highest quality available. Where available, we use aerospace quality components with metal body, copper terminals, and threaded locking rings.

ONBOARD COOLING SYSTEM

Every Axiom Pro-series machine offers a liquid-cooled electro spindle. Our innovative system replicates an automotive cooling system, where a high-volume pump pushes coolant (or antifreeze) through through the electro spindle, and dissipates the heat with a radiator and fan assembly. No buckets, no hoses, no aquarium pumps. No Drama.

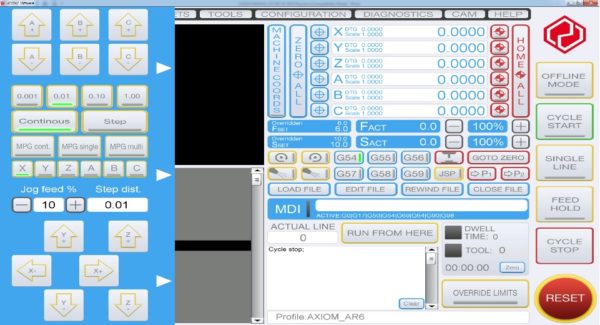

UCCNC CONTROLLER

The BG Precision spec i2R CNC Router for the Australian market is fully PC based controlled by UCCNC industrial controller and software. This PC based control allows for real time feedback of machine position to minimise mistakes. There is unmatched graphical user feedback to the operator. It is compatibility with a range of common CAM packages. Most importantly it is very intuitive operation for fast learning.

PROXIMITY SENSORS

These magnetic sensors act as the CNC’s eyes. They allow you to ‘home’ your machine so it knows where the spindle is in relation to the working envelope. Noticeably absent in many of our competitor’s machines, these sensors prevent the gantry from colliding with the stops when you run it to the extent of its travel.

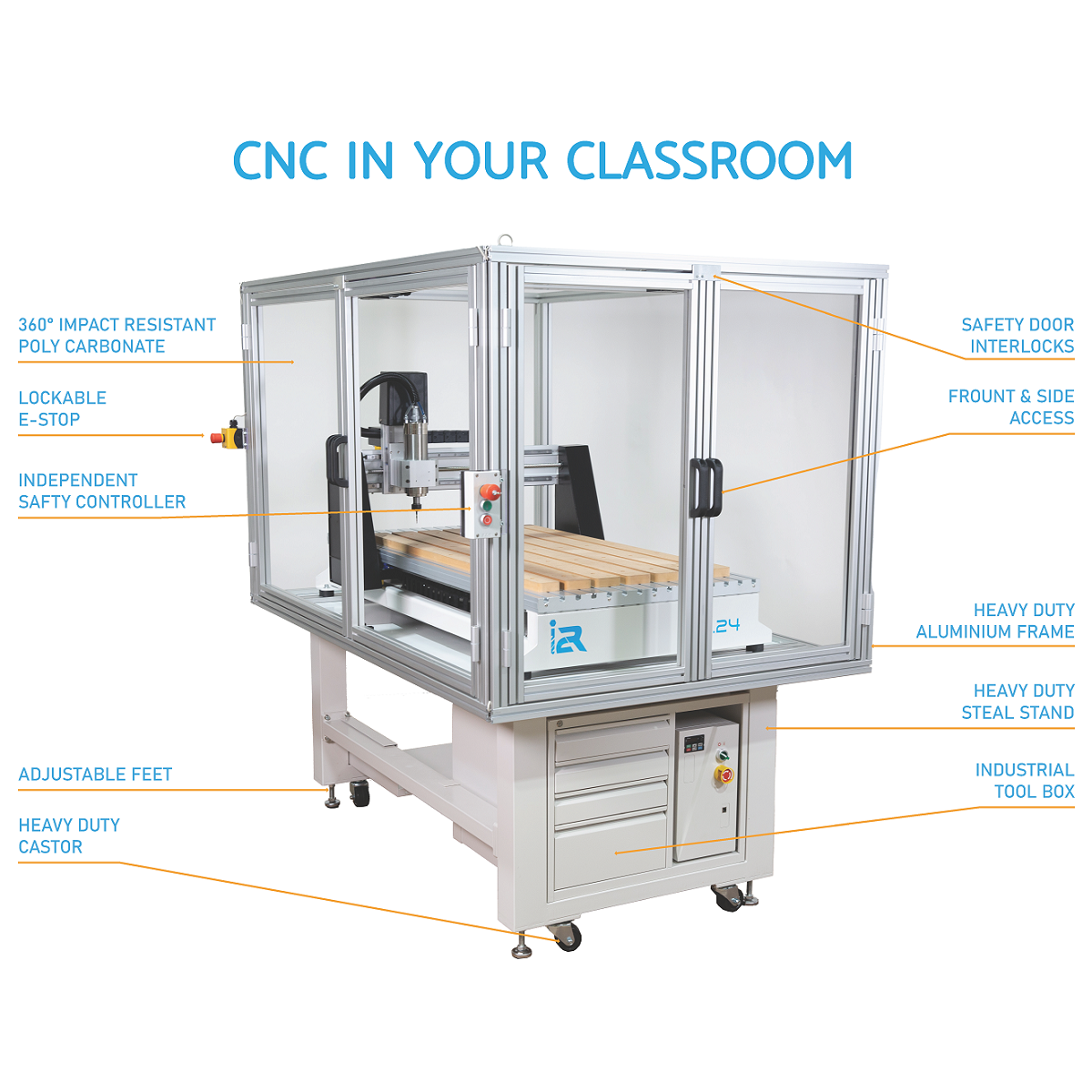

SCHOOL or EDUCATIONAL FACILITY?

Small Format CNC for Schools

All of our small format CNC systems such as the i2r, Axiom and Symbiosis can easily be configured with the following:

- High quality aluminium extrusion frame

- Easy assembly and mounting of auxiliary components

- 360 degree polycarbonate clear panel on all sides

- Large interlocking doors allow easy access

- Machine working area is locked out while the machine is active

- Three button panel with lockable E-stop, Green LED to indicate machine active or not and a “Stop Cycle” button

- Addition E-Stop mounted on opposite side

- Button panel, E-stop and door interlocks fully integrated with machine and PC control software

i2R A-Series CNC MODELS

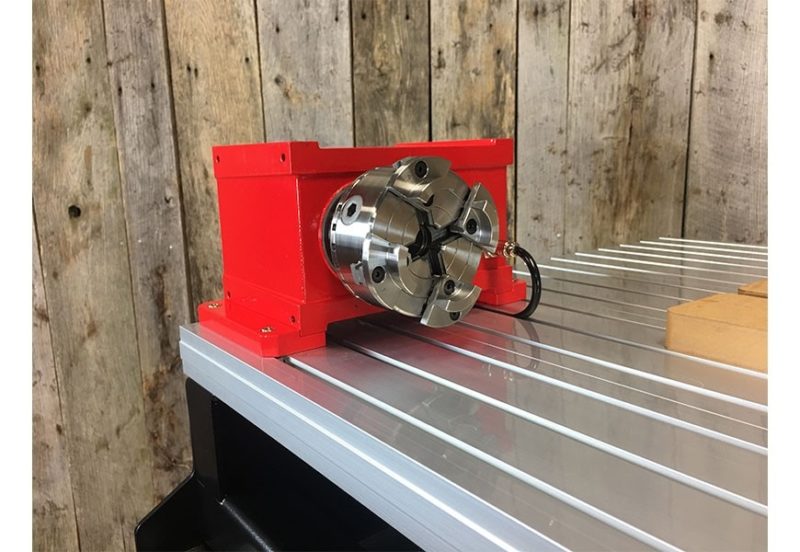

i2R CNC ACCESSORIES

i2R A-Series CNC SPECIFICATIONS

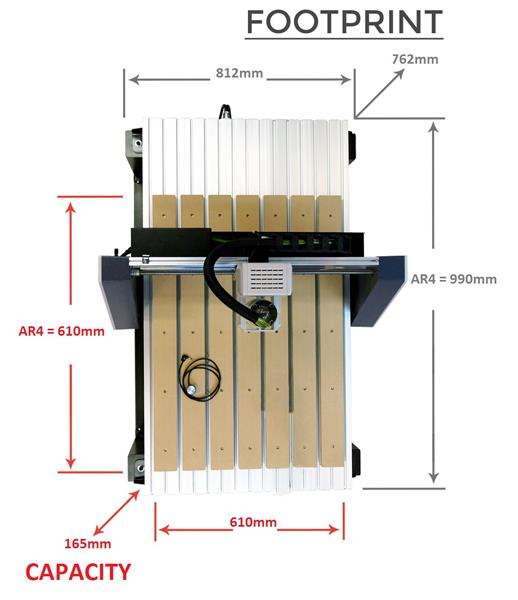

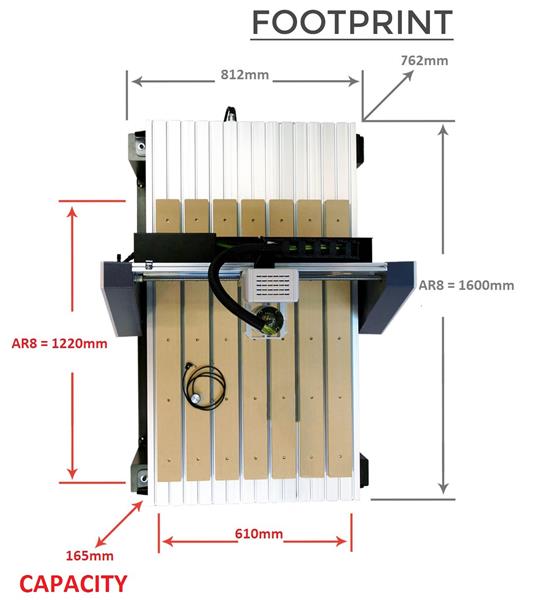

| i2R A22 / A23 / A24 | i2R Specifications |

|---|---|

| Travel in X axis | 610mm |

| Travel in Y axis | A22 = 610mm | A23 = 915mm | A24 = 1220mm |

| Travel in Z axis | 150mm |

| Overall footprint | A22 = 995L x 950W x 770H (mm) A23 = 1300L x 950W x 770H (mm) A24 = 1600L x 950W x 770H (mm) |

| Dimensions when shipped crated | A22 = 1070 x 990 x 840 (mm) A23 = 1347 x 990 x 840 (mm) A24 = 1651 x 990 x 840 (mm) |

| Machine weights | A22 = 120 kg A23 = 135 kg A24 = 150 kg |

| Bottom of collet to Tslot table height | 165mm |

| Rapid Feed rate | 6000mm/min (83mm/sec) in XY 2000mm/min (33mm/sec) in Z |

| Spindle Options | ER20 High power water cooled HF spindle 0-24,000RPM |

| Software Compatibility | PC Based Ethernet controller running UCCNC software |

| Drive system Electronics | High power stepper motors |

| Limit and homing sensors | Inductive sensors running on 12V DC on XY and Z |

| Drive system | 16mm Ballscrew drives on XY and Z | Repeatability within 0.05mm |

| Thrust support | Double angle contact bearings preloaded at thrust end of ballscrew support |

| Linear motion system | Profiled linear rails on all axes. |

| Cable management | Full cable management on all axes |

| Core components | Steel base | Cast Y cross member and up stands | Custom Aluminium extrusion bridge |

| Machine bed | Tslot table with integrated MDF spoil-board as standard |

| Tool length sensing | Configured for conductive tool touch off sensing |