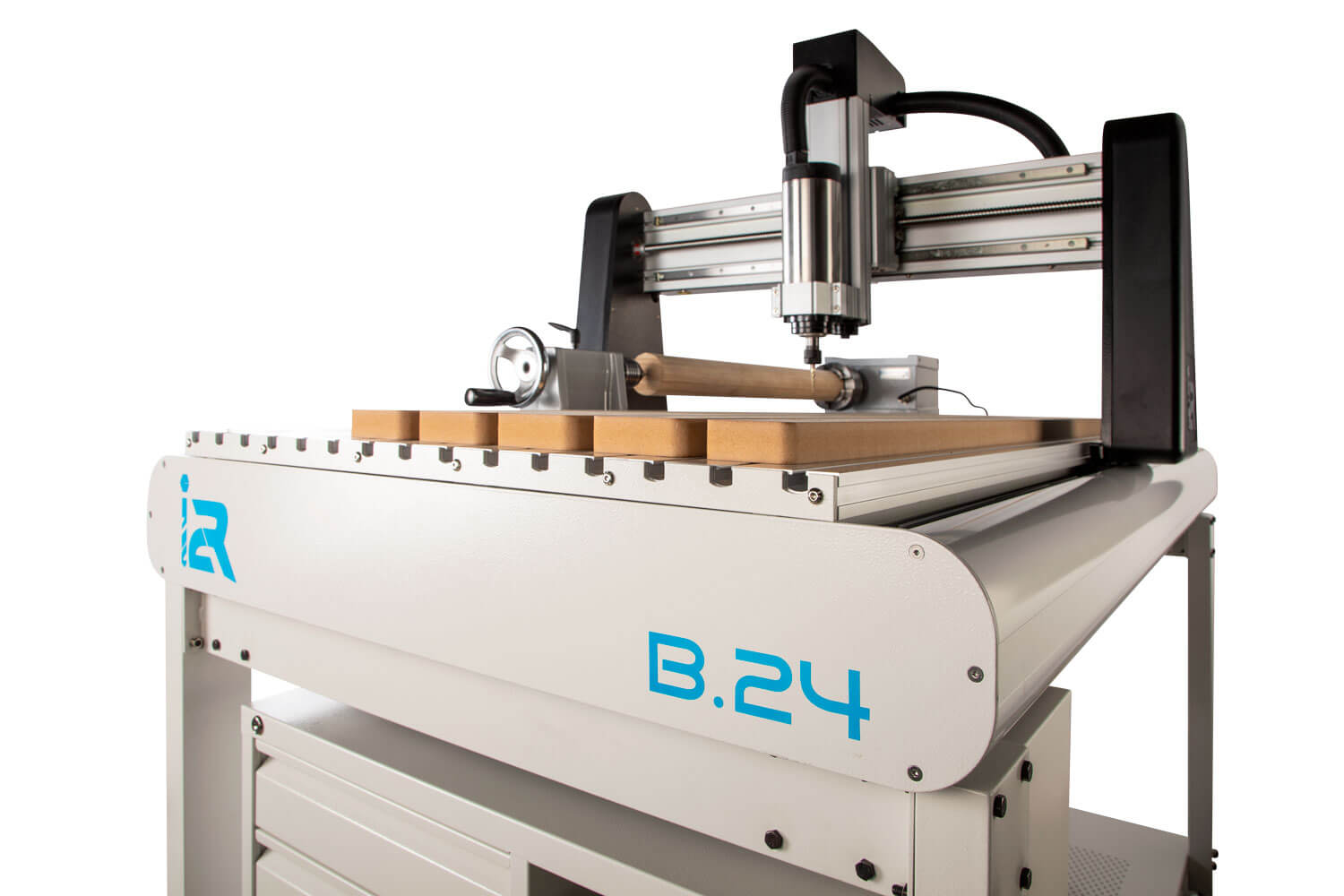

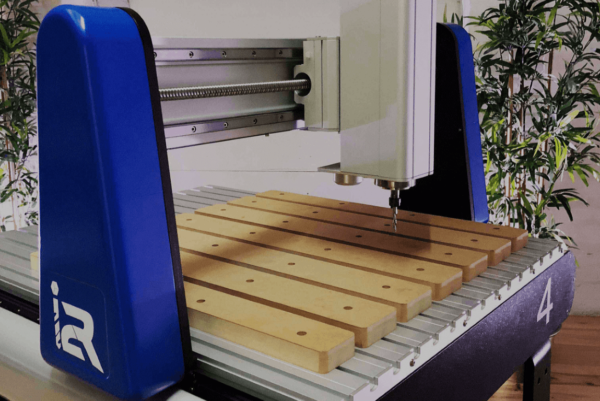

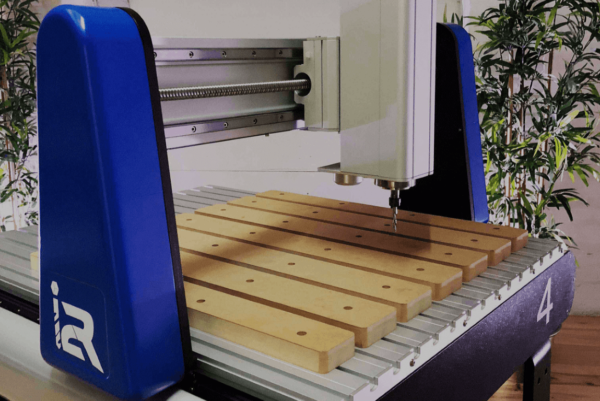

i2R B-Series CNC ROUTER

Rarely does the least expensive solution possess best-in-class features…

That changes with the launch of the new i2R B-Series CNC Router. The best technology and components have been selected to build what will surely be the new king of the entry-level CNC market.

Targeted specifically at the first-time CNC user, the new i2R lineup will be supported with a comprehensive manual and video library which are intended to dramatically shorten a new user’s learning curve.

Our i2R CNC machines combine high quality components with precise engineering in order to provide you with an extremely capable power house, entry-level, CNC system.

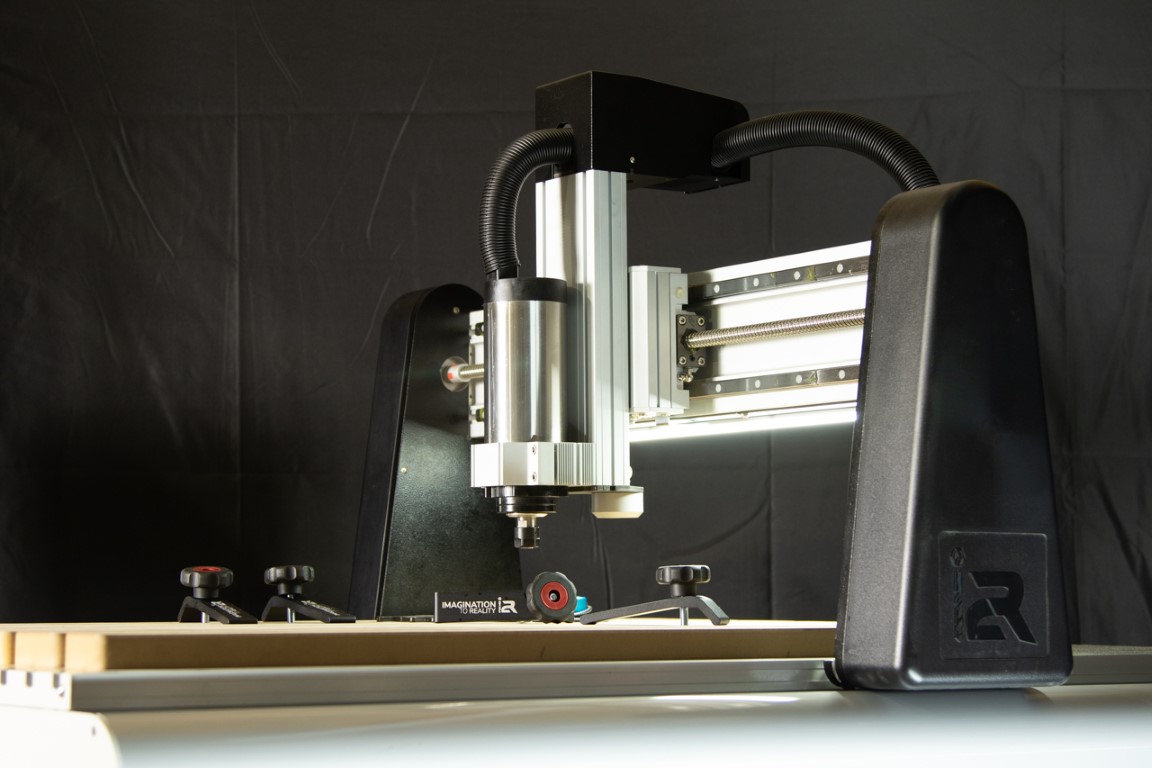

The black, i2R CNC-UCCNC line is configured to work with the innovative UCCNC technology, allowing for a PC based control system. These machines are available in three sizes. Each one is engineered for precision with prismatic linear guides, a fully recirculating ball screw drive system, and an aluminum T-slot table. We also provide a full complement of accessories ensuring that you’ll receive a package that’s specifically tailored to your CNC needs.

If you’re looking into buying your first CNC or looking to upgrade, the i2R lineup has what you need. Put your mind at ease knowing that every BG Precision machine is backed by full customer support and warranty.

i2R CNC Routers – Professional and affordable

i2R CNC Advantage

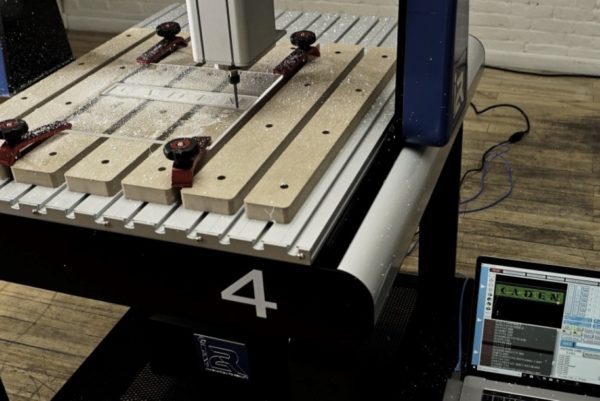

UCCNC Software PC Controlled

UCCNC is a full G-code CNC controller which allows the machine to be used with CAM packages such as Vectric. It allows you to control the i2R CNC router straight from your computer. From there you can start machining your project.

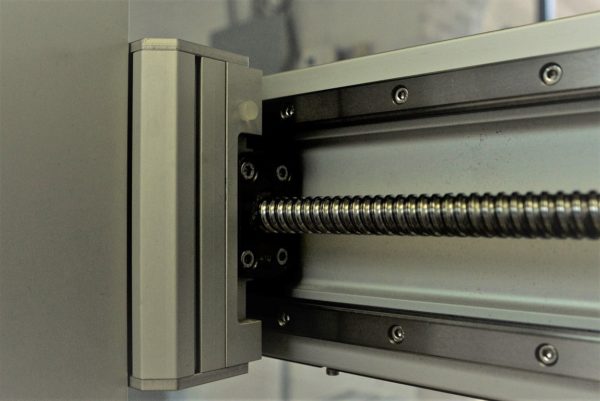

Precision Ball Screws

Motion on every axis of every i2R machine is controlled by high-precision ball screws. These ball screws utilize recirculating ball bearings to provide close tolerance and offer unmatched accuracy. Their ability to create low internal friction, while withstanding high thrust loads at high rates of speed, is paramount to the accuracy of each i2R CNC machine.

Cast Gantry Support

Heavy components travelling at a high rate of speed generate high forces of inertia. The horizontal gantry support (located beneath the table), and the vertical gantry legs take the brunt of that force. Each gravity cast aluminium component is powder coated and engineered to be completely overqualified for their job.

Z-Axis Automatic Touch Off Tool

Every i2R CNC machine comes standard with an automatic touch off tool for accurately determining your Z zero. Simply slide the tool touch-off device beneath the bit, initiate the ‘Auto Touch-Off’ command on your UCCNC interface, and the bit length will automatically be determined and stored in the UCCNC software.

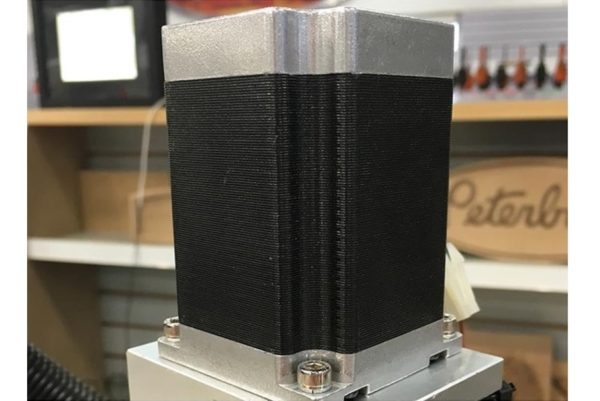

High Torque Stepper Motors

Each axis is controlled by a NEMA 23 equivalent high-torque stepper motor. Each fast, device is rated for high duty cycles, and will provide thousands of hours of trouble-free precision.

High Rigidity Aluminum Frame

Our structural aluminum frame is rigid, and accurate. It supports the weight of your i2R CNC machine with ease. The frame is build around a solid base and offers mounting flanges in each corner to secure your machine to a optional stand, or your work surface.

Precision Linear Guide Rails

Our linear guide rails utilize recirculating bearings between a prismatic rail and a bearing block. The coefficient of friction on our linear guides is only a small fraction of what is created by traditional round guides, and are able to take loads in all directions. This is how our CNC machines achieve high precision and greatly enhanced moving accuracy.

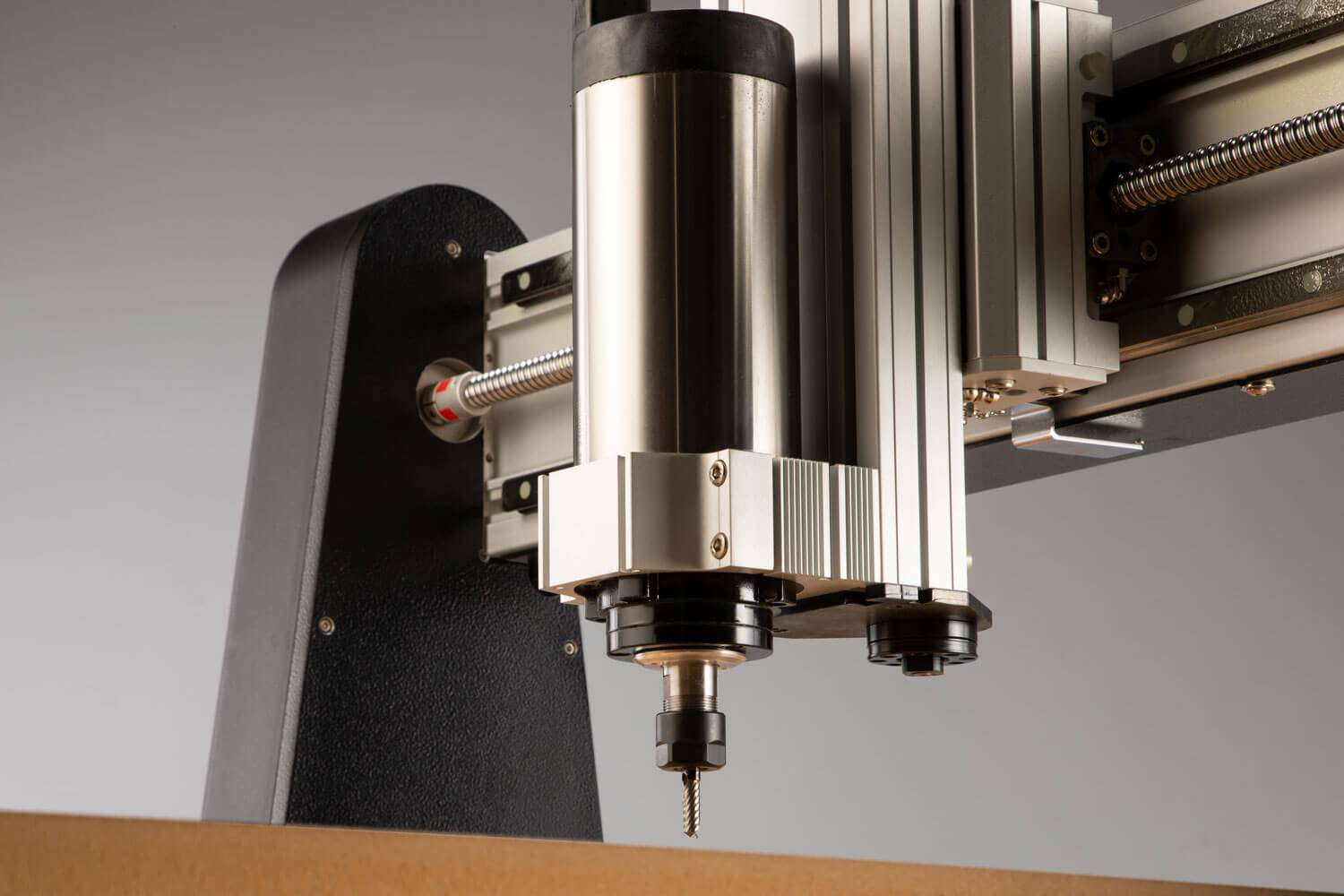

Air Cooled Spindle

Every i2R CNC machine comes with a standard VFD Driven, High Frequency air cooled spindle. At 1.5Kw, with max speed of 24,0000 RPM, it is silent yet powerful. spindle capable of performing any job.

Interlocking Aluminum Table

This is a seriously strong table. The massive 30mm thick extruded aluminium table provides a strong, flat surface to support your material. Integrated T-slots allow placement of hold-down clamps in any location, and a sacrificial MDF spoil board ensures that your table will always remain flat and damage free.

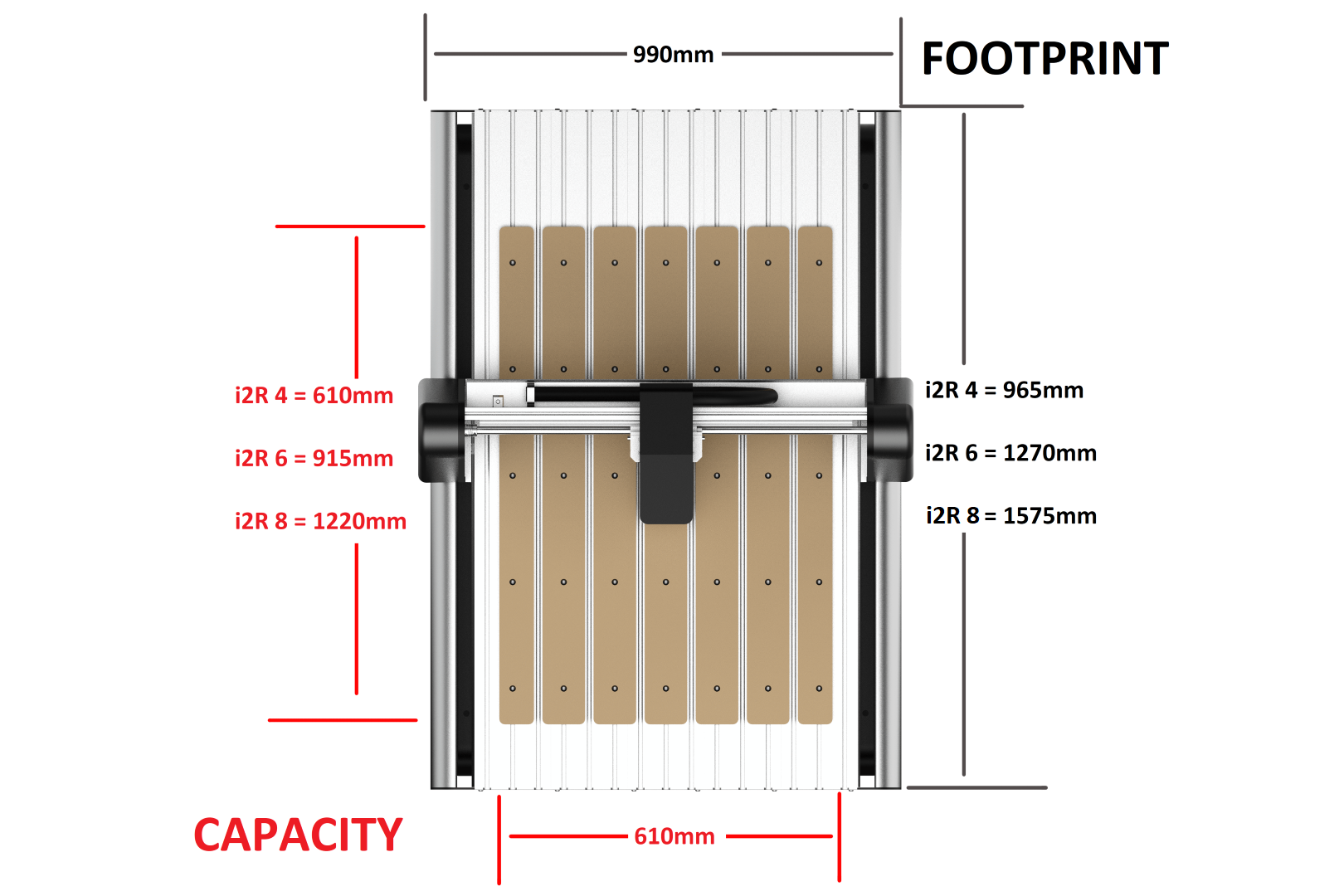

i2R CNC Router Models

Specifications

| X axis travel | 610mm |

| Y axis travel | B22 = 610mm B23 = 915mm B24 = 1220mm |

| Z axis travel | 135mm |

| Table work area | B22 = 939 x 720 mm B23 = 1245 x 720 mm B24 = 1549 x 720 mm |

| Electro Spindle | 1500W (2HP) ER 16 Collet (1-10mm) |

| Spindle speed | 0-24,000 RPM |

| Rapid feed rate | 3500mm/min |

| Precision Linear Guideway | X/Y/Z |

| Precision BallScrew | X/Y/Z |

| BallScrew Diameter | 15mm |

| Positional Accuracy | +/- 0.15mm |

| Power requirements | 220V, 50Hz, 10A, 1-Phase |

| Working Table | High rigidity Aluminum Extrusion |

| Gantry bridge | High rigidity Aluminum Extrusion |

| Gantry Supports | Aluminum billet machined |

| Gantry Clearance | 200mm |

| Machine Base | All Welded Steel Frame |

| Machine Dimensions | B22 = 965 x 990 x 711 mm B23 = 1270 x 990 x 711 mm B24 = 1575 x 990 x 711 mm |

| Shipping Dimensions | B22 = 1050 x 990 x 520 mm B23= 1400 x 990 x 520 mm B24 = 1680 x 990 x 520 mm |

| Machine Weight | B22 = 100Kg B23 = 130Kg B24 = 160Kg |

| Tool Touch Off | Included |

| Controller | UCCNC PC Control Software |