5.0 Robotics – EXECUTIVE SERIES CNC ROUTER

EXECUTIVE | Having the power to put plans or actions into effect

Named after the term EXECUTIVE, which by definition means having the power to put plans or actions into effect, the Executive CNC ROUTER lives up to this reputation.

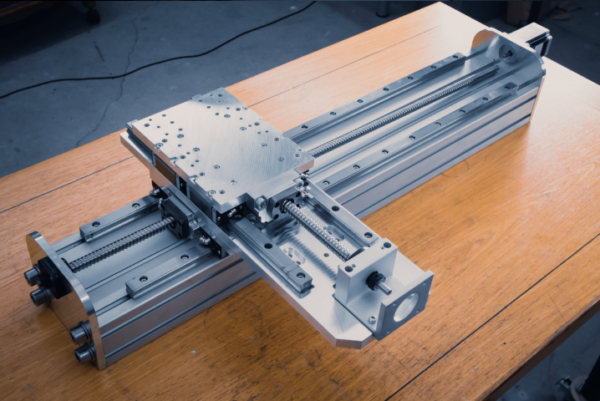

The Executive CNC ROUTER by 5.0 Robotics will be offered in two sizes. The Executive 8 (1220x610mm) and The Executive 16 (1220×1220). This series represents the most advanced design development working with the UCCNC controller on a small format CNC router platform. This series caters to users with high production requirements in a small format offering high speed, torque and precision capabilities that can only be found high end machines but for fraction of the cost.

The 5.0 Robotics Executive CNC ROUTER offers a high quality Italian, ER25 2.2KW electro-spindle with ceramic bearings by TeknoMotor as standard. All Executive machines utilize 16 mm precision ball screws, massive HIWIN prismatic guides, a robust steel frame, and interlocking aluminum table. In addition, the integrated MDF spoil boards promise you the all precision you need with an upgrade option for an industrial vacuum table to increase productivity.

THE EXEC HARDWARE PLATFORM

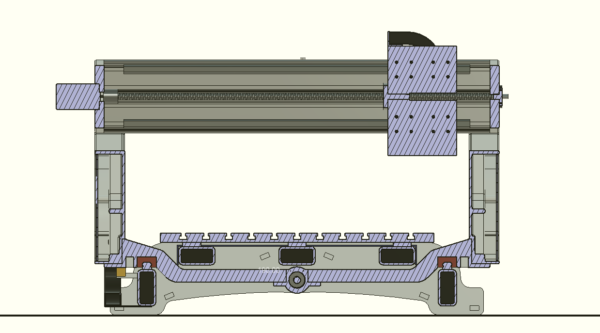

The only way to build any industrial CNC platform is on a structural steel frame and there is no compromise on the Exec CNC Router. The steel used is thick walled box iron and laser cut plate. You will not find a stiffer CNC router platform

- Fully welded steel frame

- 5mm steel box section frame elements

- FEA analyzed upstands and main cross beam to maximize strength

- Full ballscrew drive system on all axis

- 20mm Heavy duty HIWIN profile linear rails on all axis

- High load thrust bearings on all axis

- 610 or 1220 travel in X

- 1220 travel in Y

- 200mm of Z throat access | 150mm of travel

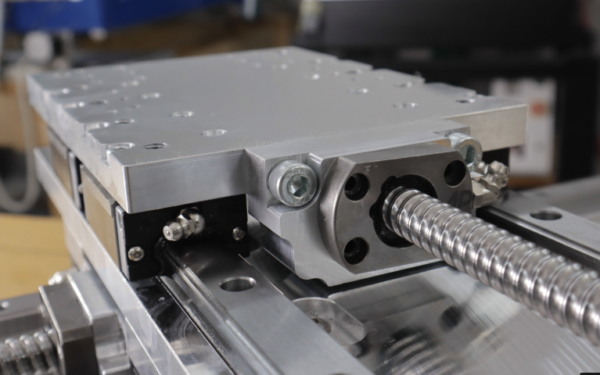

FULL BALLSCREW DRIVE SYSTEM

Superior Accuracy, Efficiency, Speed and No Backlash.

Ball screws offer a high level of mechanical efficiency, can carry remarkably heavy loads and produce minimal friction. This is because they are designed with a nut in which ball bearings circulate. The ball bearings create a smooth gliding surface for the screw, thereby reducing friction and subsequently increasing the ball screw’s lifespan.

Motion on every axis of the EXEC CNC Router is controlled by high-precision ball screws. Their ability to create low internal friction, while withstanding high thrust loads at high rates of speed, is paramount to the accuracy of the EXEC CNC Router

HEAVY DUTY HIWIN LINEAR RAILS

The EXEC CNC Router is built on heavy duty HIWIN profiled linear rails. The profiled linear rails are one of the best linear motion systems for machine accuracy.

The coefficient of friction on linear guides is only a small fraction of what is created by traditional round guides and can take loads in all directions. With these features, our CNC machines achieve the highest level of system accuracy and greatly enhanced moving accuracy to allow quality surface finish when machining woods, plastics and alloys.

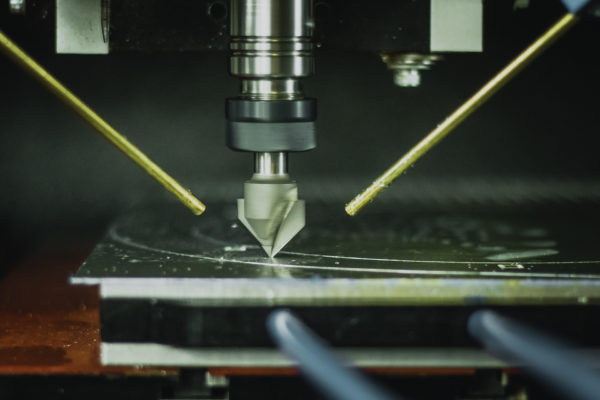

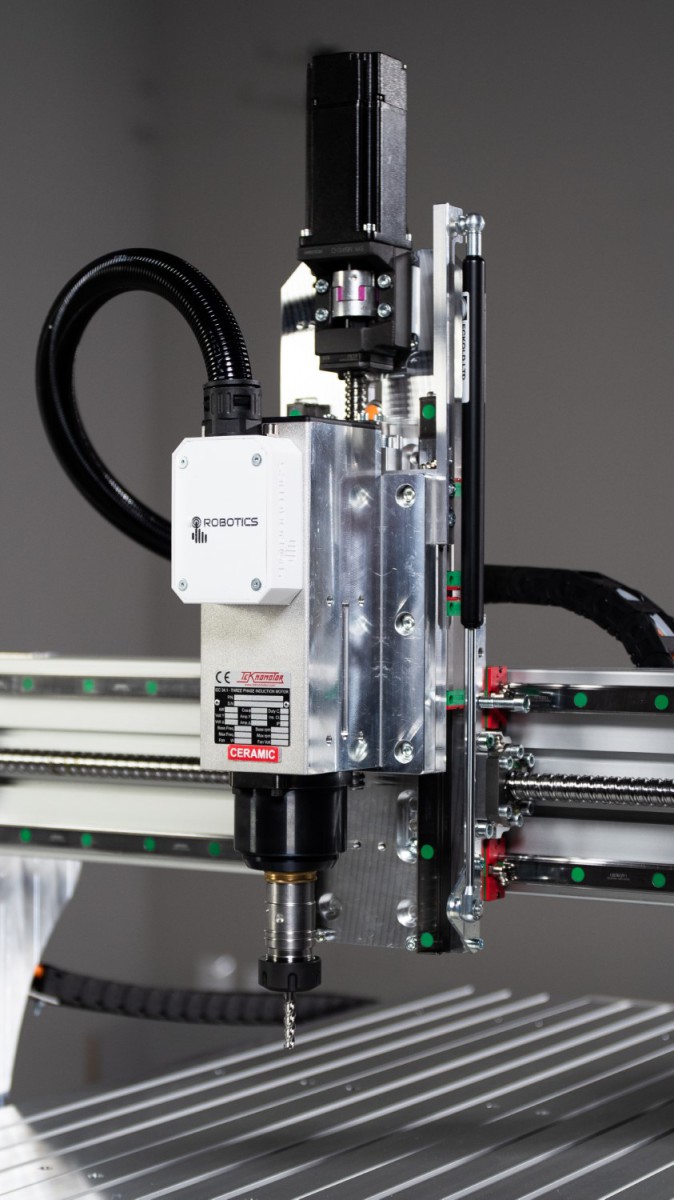

THE EXEC SPINDLE SYSTEM

Our Executive CNC ROUTER offers a high quality Italian, ER25 2.2KW electro-spindle with ceramic bearings by TeknoMotor as standard.

- Fan cooling to help heat dissipation

- All spindles come with a fully balanced collet nut

- Max RPM 24000

- Driven through a VFD so all fully on/off and speed controlled with software

OPTIONAL UPGRADE:

- High Quality 2.2kW QTC solution using HSK30 tool holders

- High Quality 2.2kw ATC ISO20 Italian Spindle with Ceramic Bearings

THE EXEC BED SYSTEM

As standard the Exec CNC Router comes with a high rigidity interlocking Aluminium T-slot table with integrated MDF sacrificial spoil board

The massive 30mm thick extruded aluminum table provides a strong, flat surface to support your material. With integrated hold-down T-slot channels allowing placement of clamps and other accessories in any location and a sacrificial MDF spoil board ensures that your table will always remain flat and damage free

OPTIONAL UPGRADE: Industrial vacuum table to increase productivity

THE EXEC DRIVE TRAIN

- 400W Delta Closed Loop Servos as standard

- Significantly improved cable management and motor protection

- High voltage high torque AC amplifier system

- Fully digital motor amplifiers

- Up to 10,000mm/min rapids

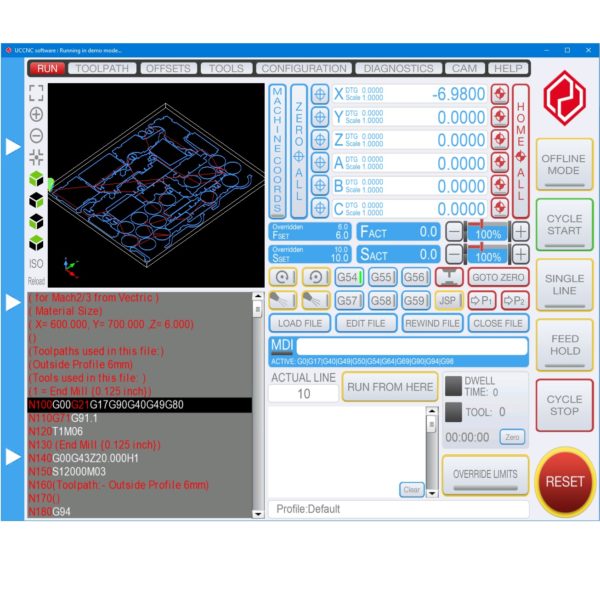

THE EXEC CONTROL PLATFORM AND INTERFACE

Machine comes as standard with full UCCNC PC based control system with integrated 3 Axis and spindle control. This PC based control allows for real time feedback of machine position to minimize mistakes. There is unmatched graphical user feedback to the operator. It is compatible with a range of common CAM packages. Most importantly it is very intuitive operation for fast learning.

- Ethernet connectivity for industrial performance

- Unlimited functionality

- Intuitive user interface

- Endless customization

- International User community with web forum support

THE EXECUTIVE CNC ROUTER – ENGINEERED WITH A DIFFERENCE

ENGINEERED using Finite Element Analysis – FEA

Heavy components traveling at a high rate of speed generate high forces of inertia. The horizontal gantry support (located beneath the table), and the vertical gantry legs take the brunt of that force.

The EXEC CNC Router has undergone full Finite Element Analysis (FEA) of the upstands and main cross beam to maximize strength of the bridge assembly. These components are truly engineered to the highest degree and are the reason behind the EXEC CNC Router superior strength.

MANUFACTURED Custom Design Components

Common mistakes seen in the design of CNC machines is a weak connection between the bridge and the horizontal gantry support which the long axis ballscrew drives. The component of the assembly is called the gantry upstand.

From the FEA it is apparent that a strong upstand is the critical component in bringing the entire assembly together and the EXEC CNC Router upstand is a CNC work of art itself. Machined from 80mm billet aluminum its been dished out to reduce weight and inertia on the bridge assembly but left with critically located stiffening ribs internally.

NEXT LEVEL Assembly Processes

As the welded steel frame of the EXEC CNC Router is the base for the Tslot many addition steps are taken to ensure the bed is perfectly aligned with the machine gantry and truly flat.

The machine itself during the assembly process is used to skim alloy strips tramming them flat. The Aluminium Tslots table is then bolted on top. This process results in the most accurately trammed bed design possible and results in minimal variation across the router bed. We still recommend mounting your spoil board surface and machining this for the best and most accurate on site bed tram setup.

NO COMPROMISE Structural Design

The distance from the tip of the cutting tool all the way to bridge can create a strong moment when a cutting force is applied and if not treated seriously can result in inaccuracies on your work, poor surface finish and even broken bits.

To counteract this an 80 x 160mm aluminium bridge that we’ve used in the larger tabletop machines up to 2000mm wide has been implemented on the EXEC CNC Router

INGENIOUS Design layout

The EXEC CNC Router has been designed with serviceability and maintainability in mind.

After many years working on many different brands of CNC machines feedback would suggest replacing, adjusting or maintaining some parts of a CNC can be very difficult and time consuming.

All components of the EXEC CNC Router have been placed with this in mind and while protected where needed are easily accessible for ease of serviceability.

EXEC CNC Router Table of Specifications

| Exec 8 | Exec 16 | |

|---|---|---|

| Table Working Area | 1220 x 610 mm | 1220 x 1220 mm |

| X axis | Nema 23 High Torque Steppers | Nema 34 NM High Torque Steppers |

| Y axis | Nema 23 High Torque Steppers | DUAL Nema 34 NM High Torque Steppers |

| Z axis | Nema 23 High Torque Steppers | Nema 23 NM High Torque Steppers |

| Linear Guides | 20mm Profile Linear Guides on all axis with 4 carriages per axis | 20mm Profile Linear Guides on all axis with 4 carriages per axis |

| Drive Motion | 16mm Ballscrews on X, Y , Z Axis | 16mm Ballscrews on X, Y , Z Axis Dual Ballscrews on Y Axis |

| Rapid Feed Rate | Up to 10,000mm/min | Up to 10,000mm/min |

| Repeatability tolerance | ±0.05/300mm | ±0.05/300mm |

| Spindle System | 2.2kw ER25 air cooled Spindle (0 – 24,000 RPM) | 2.2kw ER25 air cooled Spindle (0 – 24,000 RPM) |

| Gantry Bridge | 160 x 80mm heavy duty Maytech Alloy Bridge | 160 x 80mm heavy duty Maytech Alloy Bridge |

| Gantry Supports | FEA designed webbed Aluminum upstand construction | FEA designed webbed Aluminum upstand construction |

| Gantry Clearance | As standard 200mm clearance – and repositionable Z height | As standard 200mm clearance – and repositionable Z height |

| Z AutoTouch Off | Included | Included |

| Controller | High voltage stepper controller system with full UCCNC control. Servo options available | High voltage stepper controller system with full UCCNC control. Servo options available |

| Power requirements | 230v 1phase – main machine will run off a 10A single phase supply | 230v 1phase – main machine will run off a 10A single phase supply |